| Air jet loom technical parameters | ||

| Item | air jet loom configuration | Remark |

| Nominal reed space | ◊150,◊170,◊190,◊210,◊230, ◊280,◊320,◊340,◊360 cm | Useful reed width:Below 280cm cut 0-60cm Above 280cm cut 0- 80cm |

| Drive | Motor choose by reed. Shedding type | |

| Weft selection | ( )set weft storage,( )main nozzle, any weft | ◊2 color;◊4 color; ◊6 color |

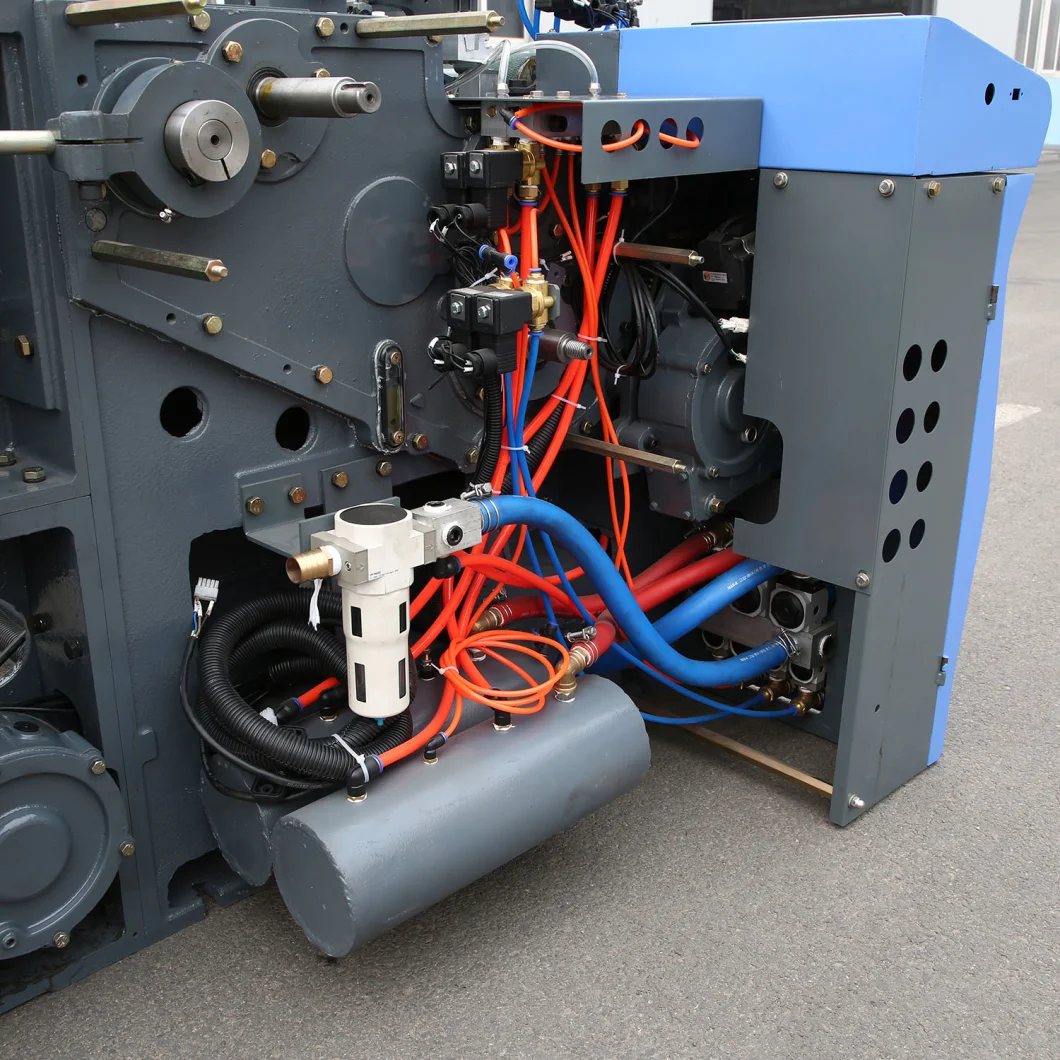

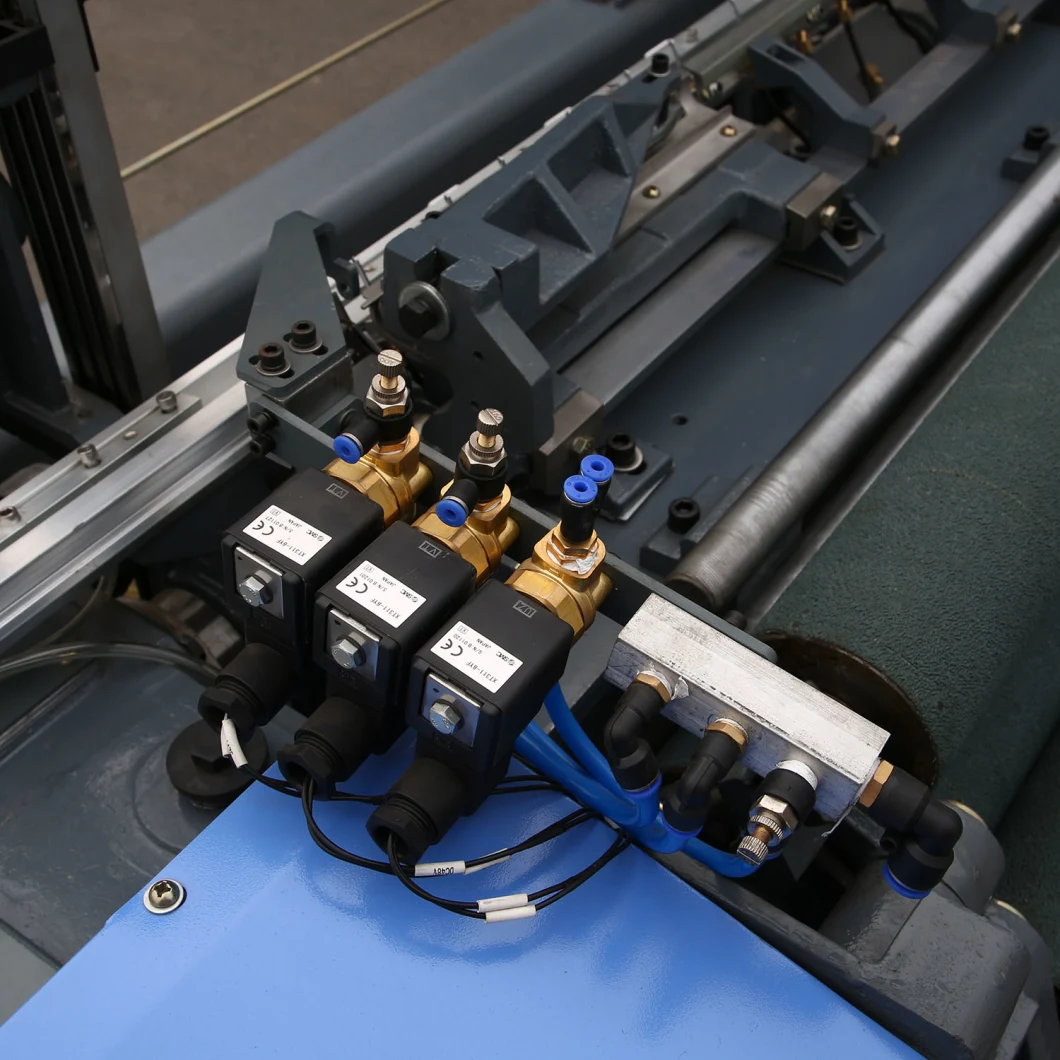

| Weft insertion | Electronic control mail, auxiliary nozzle relay weft, with auxiliary main nozzle, SMC solenoid valve from Japan | |

| Beating | More support feet beating solid shaft, With weight, Crank linkage beating | above 280cm six-bar linkage, below 280cm four-bar beating |

| Let off | Electronically controlled continuous positive let-off, suitable for ◊φ800 beam ◊φ1000mm beam | |

| Take up | ◊electronic take up ; ◊Mechanical take-up | ◊sand roller; ◊double pressure roller; ◊rubber roller;◊barbed leather roller |

| Winding | ◊inside the machine winding ◊outside the machine winding | ◊inside the machine winding maximum roll diameter 550mm ◊outside the machine winding maximum roll diameter 1200mm |

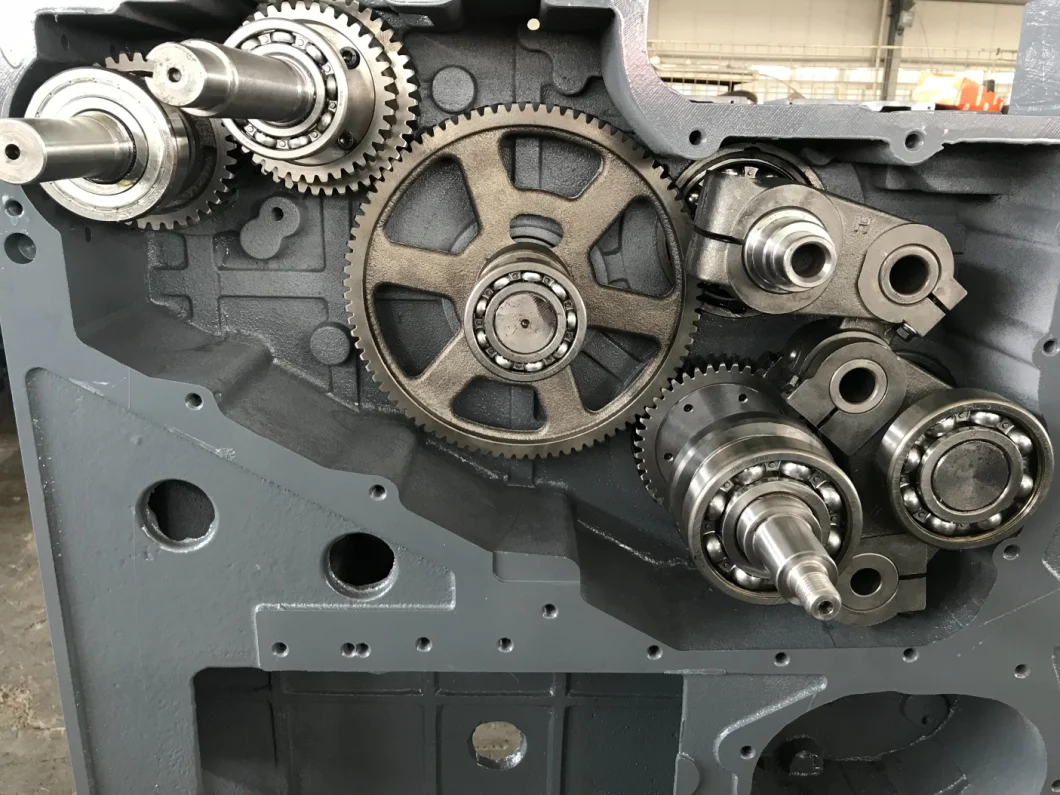

| shedding | ◊positive cam shedding(up to 8)shaft ◊crank shedding (4)shaft ◊electronic dobby shedding(up to 16)shaft | Cam box and dobby manufacture: ◊Bintian ◊Staubli ◊Niupai |

| Shedding cams | ◊1/1 ;◊ 2/1 ; ◊3/1 ; ◊2/2 ;◊4/1 shaft | |

| Heald frame | Number of New Light heald frames | |

| Heald wires | Heald wires ◊J type 331 ; ◊ O type 330 | |

| cutter | Mechanical shears | |

| Selvage | Planetary gear cutter edge institution | |

| temple | 30 hoops temple in the cloth above | |

| Back beam | Double back beam, positive loose warp | |

| Control box | ◊7" ◊10.4" touch screen ; computer control system ; process parameters, monitoring, self-diagnosis display | |

| Parking device | 4 color indictor show failure A,broken warp: 6 row drop pin; B,cut weft: double weft feeder C,selvage: near switch D,catch weft: sensor | |

1.Saving running cost for customer

YC910 series air jet loom,weaving speed improve 20%. Air consumption reduce 40%,can

save lot of electricity fee for weaving factory every year.and also can save the air compressor equipment purchasing costs.

Adopting DSP electronic control system,both the calculation and transmission speed become much higher and no interference. Germany Siemens integrated suppliers of a complete set of technology, deeply provide powerful guarantee for high speed and energy saving.

3.Eccentric Beating-shaft

Eccentric type rocker bring better balance and stability, to reduce the vibration machine running big defect, make the ground vibration reduced about 35%

4.Double beam to protect the heddle frams

Upgrading of heald frame guide device, with double beams, before and after adding heald frame plate, reduce the machine of heald frame vibration in high speed, so as to guarantee the stability of the loom high speed at the same time reduce the wear and tear of heald frame.

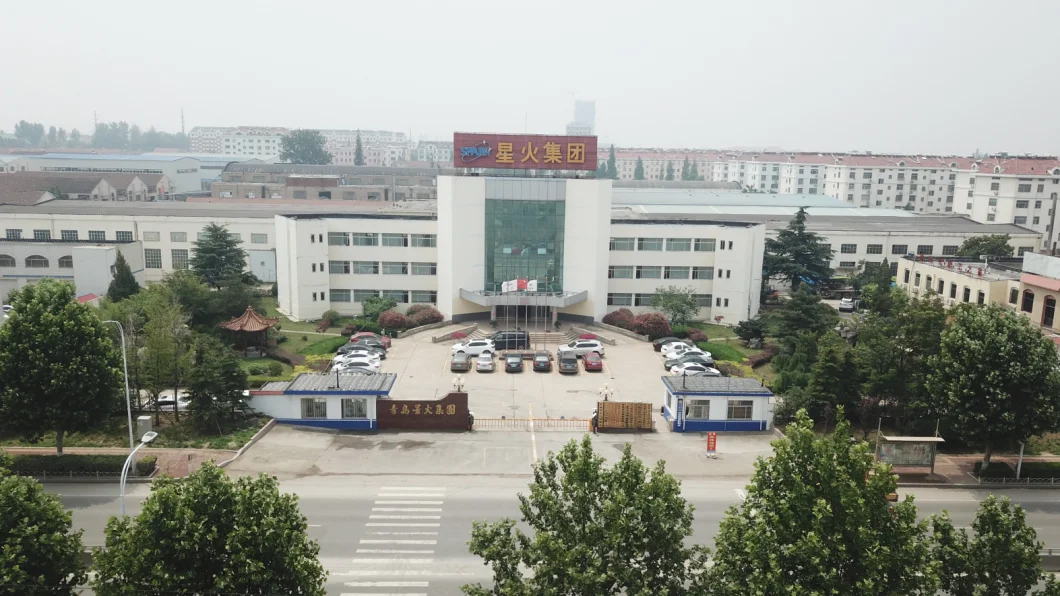

The company have 2000 employees covers an area of 400,000 square meters. It has 800 more mechanical ste equipped with variety of advanced processing technology and owns a world-leading CNC machining center. The company has manufactured textile machine product since 1980, and it has developed the largest shuttless loom manufacture in China with gaining of certificate ISO9001 on international quality assurance standards at earlier time.

Qingdao Spark Yinchun Textile Machinery Co.Ltd, a subsidiary of group of Qingdao Spark Textile Machinery&Textile Co.Ltd, is a member of China Textile Machinery Association. It has obtained the "GB/T19001-2008" quality system attestation, "GB/T19022-2003" measurement mannagement system attestation and was honored as AAA-level enterprise by standardization Administration of the P.R.C. Besides, Qingdao Saprk Yinchun textile Machinery Co.Ltd. is a major force in drafting and developing the industrial standards of the jet looms. Whit decades of manufacturing experience, the professional of the company using the world leading technology, have manufactured JW series of water jet loom and YC series of air jet looms to reach a world level. Its stable performance assures the clients a comfortable using experience and the company is looking forward to your coming and cooperation.